A frame is a structural element that provides support and shape to a building or other structure. It is typically made of wood, steel, or other materials and is designed to bear the weight of the structure and distribute it evenly to the ground. Frames are essential components of buildings, bridges, and other structures, as they provide stability and strength.In construction, frames are used to create the skeleton of a building, which is then filled in with walls, floors, and other elements to create a complete structure. Frames can be made of various materials, including wood, steel, concrete, and aluminum, depending on the specific requirements of the project.There are several different types of frames used in construction, each with its own unique characteristics and advantages. Some common types of frames include:- Wood frames: Wood frames are one of the oldest and most traditional types of framing used in construction. They are lightweight, easy to work with, and can be easily customized to fit the specific needs of a project. Wood frames are commonly used in residential construction, as well as in smaller commercial buildings.- Steel frames: Steel frames are strong, durable, and resistant to fire and pests, making them an ideal choice for larger commercial and industrial buildings. Steel frames are also lightweight and can be easily prefabricated off-site and assembled on-site, which can help to reduce construction time and costs.- Concrete frames: Concrete frames are extremely strong and durable, making them ideal for buildings that need to withstand heavy loads or harsh environmental conditions. Concrete frames are commonly used in high-rise buildings, parking structures, and other large-scale projects.- Aluminum frames: Aluminum frames are lightweight, corrosion-resistant, and easy to work with, making them a popular choice for residential and commercial construction projects. Aluminum frames are also recyclable, making them a sustainable choice for environmentally conscious builders.In addition to providing structural support, frames also play a crucial role in the energy efficiency and sustainability of a building. By using high-quality materials and incorporating energy-efficient design features, such as insulation and thermal breaks, frames can help to reduce energy consumption and lower operating costs.Overall, frames are essential components of any building or structure, providing support, stability, and strength. By choosing the right type of frame for a project and incorporating energy-efficient design features, builders can create structures that are not only safe and durable but also environmentally friendly and cost-effective.

Shell is a versatile material that has been used in various industries for centuries. From construction to cosmetics, the applications of shell are vast and diverse. As a result, there are numerous important patents related to shell in different industries. In this article, we will explore some of the key industries that contain important patents related to shell.1. Construction Industry:

Shell has been used in the construction industry for centuries, particularly in the form of mother of pearl. Mother of pearl is a strong, iridescent material that is derived from the inner layer of certain shells. It has been used to adorn buildings, furniture, and decorative items for centuries. In the construction industry, there are several important patents related to the use of shell as a building material. For example, there are patents related to the use of mother of pearl in flooring, wall coverings, and decorative elements in buildings.2. Jewelry Industry:

Shell has long been used in the jewelry industry for its beauty and durability. Mother of pearl, in particular, is a popular material for making jewelry due to its iridescent quality. There are numerous patents related to the use of shell in jewelry design and manufacturing. These patents cover various aspects of jewelry making, such as cutting and shaping techniques, setting methods, and design innovations.3. Cosmetics Industry:

Shell is also used in the cosmetics industry for its exfoliating and polishing properties. Crushed shells are often used in exfoliating scrubs and polishes to remove dead skin cells and reveal smoother, brighter skin. There are patents related to the use of shell in cosmetic formulations, as well as patents related to the manufacturing processes for shell-based cosmetic products.4. Pharmaceutical Industry:

Shell has also found applications in the pharmaceutical industry. For example, calcium carbonate derived from shells is used as a dietary supplement to support bone health. There are patents related to the extraction and purification of calcium carbonate from shells, as well as patents related to the formulation and delivery of calcium carbonate supplements.5. Food Industry:

Shell is used in the food industry in various forms, such as shellfish shells for flavoring and calcium carbonate from shells as a food additive. There are patents related to the use of shell in food processing and packaging, as well as patents related to the development of new food products incorporating shell-derived ingredients.6. Automotive Industry:

Shell is also used in the automotive industry for various applications, such as in the production of lightweight components and decorative trim. There are patents related to the use of shell in automotive design and manufacturing, as well as patents related to the development of new materials and processes for incorporating shell into automotive products.In conclusion, shell is a versatile material that has found applications in a wide range of industries. From construction to cosmetics, jewelry to pharmaceuticals, shell has been used in various forms for centuries. As a result, there are numerous important patents related to shell in different industries, covering a wide range of applications and innovations. These patents reflect the ongoing research and development efforts to harness the unique properties of shell for various industrial applications.

The appendix is a small, tube-like organ located at the junction of the small and large intestines in the lower right side of the abdomen. Despite its small size, the appendix plays an important role in the immune system, as it contains lymphatic tissue that helps fight off infections. However, the appendix is not considered essential for human survival, and in some cases, it can become inflamed and infected, leading to a condition known as appendicitis.When appendicitis occurs, the inflamed appendix must be removed through a surgical procedure called an appendectomy. This procedure is one of the most common emergency surgeries performed worldwide, with over 300,000 appendectomies performed in the United States alone each year. The mainstream appendix production process involves several key steps, from the initial diagnosis of appendicitis to the surgical removal of the appendix and the post-operative care of the patient.The first step in the mainstream appendix production process is the diagnosis of appendicitis. This typically involves a physical examination by a healthcare provider, as well as imaging tests such as ultrasound or CT scans to confirm the diagnosis. Symptoms of appendicitis can include abdominal pain, fever, nausea, and vomiting, and a diagnosis must be made quickly to prevent complications such as a ruptured appendix.Once a diagnosis of appendicitis has been confirmed, the next step in the mainstream appendix production process is the surgical removal of the inflamed appendix. This procedure is typically performed under general anesthesia and can be done using either traditional open surgery or minimally invasive laparoscopic surgery. In laparoscopic surgery, several small incisions are made in the abdomen, and a tiny camera and surgical instruments are used to remove the appendix. This approach is less invasive and typically results in a faster recovery time for the patient.During the appendectomy procedure, the surgeon carefully removes the inflamed appendix and closes the incision with sutures or staples. The removed appendix is then sent to a pathology lab for examination to confirm the diagnosis of appendicitis and rule out any other underlying conditions. In some cases, the appendix may be found to contain a tumor or other abnormal growth, which may require further treatment.After the appendectomy procedure, the patient is typically monitored closely for any signs of complications such as infection or bleeding. Pain medication and antibiotics may be prescribed to help manage pain and prevent infection. Most patients are able to go home within a day or two after surgery and can resume normal activities within a few weeks.In conclusion, the mainstream appendix production process involves the diagnosis and surgical removal of an inflamed appendix in patients with appendicitis. This common procedure is essential for treating appendicitis and preventing complications such as a ruptured appendix. With advances in surgical techniques and post-operative care, most patients can expect a successful recovery and return to normal activities after an appendectomy.

Fasteners are essential components in various industries, including construction, automotive, aerospace, and manufacturing. These small but crucial components are used to join two or more objects together securely. There are numerous types of fasteners available in the market, each with its unique features and applications. In this article, we will discuss some of the most popular models of fasteners and their uses.1. Screws:

Screws are one of the most common types of fasteners used in a wide range of applications. They consist of a threaded shaft with a head at one end and are typically used to fasten objects together by turning them into a pre-drilled hole. There are various types of screws available, including wood screws, machine screws, self-tapping screws, and sheet metal screws. Wood screws are designed for use in wood applications, while machine screws are used in metal applications. Self-tapping screws are used to create their threads in materials like plastic or metal, while sheet metal screws are designed for use in thin metal sheets.2. Bolts:

Bolts are similar to screws but are typically larger and have a flat end instead of a pointed one. They are used with nuts to fasten objects together and provide a more secure connection than screws. Bolts come in various types, including hex bolts, carriage bolts, and eye bolts. Hex bolts have a hexagonal head and are used with a nut and washer for a secure connection. Carriage bolts have a rounded head and a square neck that prevents them from turning when tightened. Eye bolts have a looped head and are used for lifting or hanging objects.3. Nuts:

Nuts are used in conjunction with bolts to secure objects together. They are typically hexagonal in shape and come in various sizes to fit different bolt diameters. Nuts are available in different materials, including steel, stainless steel, and brass, depending on the application requirements. Some common types of nuts include hex nuts, lock nuts, and wing nuts. Hex nuts are the most common type and are used with bolts to secure objects together. Lock nuts have a nylon insert that prevents them from loosening due to vibrations. Wing nuts have two wings that allow for hand tightening without the need for tools.4. Washers:

Washers are thin, flat discs with a hole in the center that are placed between the nut and the surface being fastened. They distribute the load evenly and prevent the nut from digging into the surface, thereby providing a more secure connection. There are various types of washers available, including flat washers, lock washers, and spring washers. Flat washers are the most common type and are used to distribute the load over a larger area. Lock washers have teeth or ridges that bite into the surface to prevent the nut from loosening. Spring washers are curved to provide a constant tension on the nut, preventing it from loosening due to vibrations.5. Rivets:

Rivets are permanent fasteners that are used to join two or more objects together by deforming the end of the rivet to create a secure connection. They are commonly used in applications where welding or screwing is not possible or practical. There are various types of rivets available, including solid rivets, blind rivets, and tubular rivets. Solid rivets are the most basic type and are used in heavy-duty applications. Blind rivets are used in applications where access to the back of the workpiece is limited. Tubular rivets are hollow and are used in applications where a watertight seal is required.6. Anchors:

Anchors are fasteners used to secure objects to a surface that cannot support the weight or load on its own. They are commonly used in applications where screws or bolts cannot be used, such as in concrete or masonry. There are various types of anchors available, including concrete anchors, drywall anchors, and toggle anchors. Concrete anchors are used to secure objects to concrete surfaces, while drywall anchors are used in drywall or plaster walls. Toggle anchors are used in hollow walls or ceilings and provide a secure connection by expanding behind the surface.In conclusion, fasteners are essential components in various industries and play a crucial role in joining objects together securely. There are numerous types of fasteners available, each with its unique features and applications. Some of the most popular models of fasteners include screws, bolts, nuts, washers, rivets, and anchors. Understanding the different types of fasteners and their uses can help in selecting the right fastener for a specific application, ensuring a secure and reliable connection.

The Hardware scenario includes a wide range of industries that are involved in the manufacturing, distribution, and sale of physical products such as computers, smartphones, appliances, and other electronic devices. These industries play a crucial role in the global economy, as they provide the necessary tools and equipment for businesses and consumers to operate efficiently and effectively.One of the key industries in the Hardware scenario is the computer hardware industry. This industry includes companies that manufacture and sell computer components such as processors, memory, storage devices, and graphics cards. These components are essential for building and maintaining computers, which are used in a wide range of applications including business, education, entertainment, and communication.Another important industry in the Hardware scenario is the smartphone industry. Smartphones have become an essential tool for communication, entertainment, and productivity, and the industry is constantly evolving to meet the demands of consumers. Companies in this industry design and manufacture smartphones with advanced features such as high-resolution cameras, fast processors, and long-lasting batteries.The appliance industry is also a significant player in the Hardware scenario. This industry includes companies that produce a wide range of household appliances such as refrigerators, washing machines, dishwashers, and ovens. These appliances are essential for modern living, as they help to automate household tasks and improve the quality of life for consumers.The hardware scenario also includes industries that produce electronic devices such as televisions, cameras, and gaming consoles. These devices are used for entertainment, communication, and productivity, and companies in this industry are constantly innovating to create new and improved products that meet the needs of consumers.In addition to these industries, the Hardware scenario also includes companies that produce industrial equipment such as machinery, tools, and construction materials. These products are essential for businesses in sectors such as manufacturing, construction, and agriculture, and companies in this industry play a crucial role in supporting economic growth and development.Overall, the Hardware scenario encompasses a wide range of industries that are essential for the functioning of modern society. These industries provide the tools and equipment that businesses and consumers need to operate efficiently and effectively, and they are constantly evolving to meet the changing demands of the market. As technology continues to advance, the Hardware scenario will continue to play a crucial role in driving innovation and economic growth in the global economy.

The latest hardware in the market is the highly anticipated release of the new iPhone 13. With its sleek design, advanced features, and powerful performance, the iPhone 13 is set to revolutionize the smartphone industry once again. But with all these cutting-edge technologies comes a hefty price tag. So, what is the purchase price of the latest hardware?The iPhone 13 comes in four different models: the iPhone 13 mini, iPhone 13, iPhone 13 Pro, and iPhone 13 Pro Max. The prices vary depending on the model and storage capacity you choose. The starting price for the iPhone 13 mini is $699 for the 128GB model, while the iPhone 13 starts at $799 for the same storage capacity. The iPhone 13 Pro starts at $999 for the 128GB model, and the iPhone 13 Pro Max starts at $1,099 for the same storage capacity.These prices may seem steep, but when you consider the advanced features and technologies packed into these devices, it's easy to see why they come with a premium price tag. The iPhone 13 boasts a new A15 Bionic chip, which promises faster performance and improved energy efficiency. The Super Retina XDR display offers stunning visuals with true-to-life colors and deep blacks. The Pro models also come with ProMotion technology, which delivers a smoother scrolling experience and better responsiveness.In terms of camera capabilities, the iPhone 13 lineup is equipped with improved sensors and lenses that promise better low-light performance and enhanced image quality. The Pro models feature a triple-camera system with advanced computational photography features, such as ProRAW and ProRes video recording. These cameras are capable of capturing stunning photos and videos in any lighting conditions.Another standout feature of the iPhone 13 is its battery life. Apple claims that the new models offer longer battery life compared to their predecessors, thanks to the more efficient A15 Bionic chip and software optimizations. This means you can enjoy using your device for longer periods without having to worry about running out of battery.Of course, the iPhone 13 is not the only latest hardware on the market. There are also other devices such as the latest MacBook Pro, iPad Pro, and Apple Watch Series 7, each with their own set of features and price points. The MacBook Pro, for example, starts at $1,299 for the base model, while the iPad Pro starts at $799 for the 11-inch model. The Apple Watch Series 7 starts at $399 for the GPS model and $499 for the GPS + Cellular model.When it comes to purchasing the latest hardware, it's important to consider your needs and budget. While these devices come with premium price tags, they also offer top-of-the-line features and performance that can enhance your productivity and entertainment experience. Whether you're a professional looking for a powerful laptop, a creative looking for a versatile tablet, or a fitness enthusiast looking for a smartwatch, there is a device out there that can meet your needs.In conclusion, the purchase price of the latest hardware varies depending on the device and model you choose. The iPhone 13, MacBook Pro, iPad Pro, and Apple Watch Series 7 are just a few examples of the latest hardware available in the market. While these devices may come with premium price tags, they also offer advanced features and technologies that can enhance your daily life. So, if you're in the market for a new device, be sure to do your research and choose the one that best fits your needs and budget.

The Transmitter scenario includes a wide range of industries that are essential for the functioning of modern society. These industries play a crucial role in the economy and provide goods and services that are vital for our daily lives. In this article, we will explore some of the key industries that are included in the Transmitter scenario and discuss their importance in the global economy.One of the industries included in the Transmitter scenario is the telecommunications industry. This industry is responsible for providing the infrastructure and services that allow people to communicate with each other over long distances. Telecommunications companies build and maintain networks of cables, satellites, and other technologies that enable phone calls, text messages, and internet access to be transmitted around the world. Without the telecommunications industry, it would be impossible for people to stay connected and communicate with each other in the way that we do today.Another important industry included in the Transmitter scenario is the energy industry. This industry is responsible for producing and distributing the energy that powers our homes, businesses, and transportation systems. The energy industry includes a wide range of sources, including fossil fuels like oil and natural gas, as well as renewable sources like wind and solar power. Energy companies play a crucial role in ensuring that we have a reliable and affordable supply of energy to meet our daily needs.The transportation industry is also a key component of the Transmitter scenario. This industry is responsible for moving people and goods from one place to another, whether by land, sea, or air. Transportation companies operate a wide range of vehicles and infrastructure, including cars, trucks, trains, ships, and airplanes. Without the transportation industry, it would be impossible for goods to be delivered to stores, for people to commute to work, or for travelers to visit new places.The healthcare industry is another important sector included in the Transmitter scenario. This industry is responsible for providing medical care and services to people who are sick or injured. Healthcare companies include hospitals, clinics, pharmaceutical companies, and medical device manufacturers. The healthcare industry plays a crucial role in keeping people healthy and treating illnesses and injuries, and it is essential for maintaining the well-being of society as a whole.The financial services industry is also a key component of the Transmitter scenario. This industry is responsible for managing and distributing money and financial assets, including banking, investing, and insurance services. Financial companies play a crucial role in facilitating economic transactions, managing risk, and providing financial security to individuals and businesses. Without the financial services industry, it would be difficult for people to save, invest, or protect their assets.The technology industry is another important sector included in the Transmitter scenario. This industry is responsible for developing and producing the technologies that power our modern world, including computers, smartphones, software, and internet services. Technology companies play a crucial role in driving innovation, improving efficiency, and connecting people around the world. Without the technology industry, it would be impossible for us to access information, communicate with each other, or perform many of the tasks that we take for granted in our daily lives.In conclusion, the Transmitter scenario includes a wide range of industries that are essential for the functioning of modern society. These industries play a crucial role in the economy and provide goods and services that are vital for our daily lives. From telecommunications and energy to transportation, healthcare, financial services, and technology, each industry included in the Transmitter scenario plays a unique and important role in shaping the world we live in today. By understanding the importance of these industries and the challenges they face, we can better appreciate the complex web of interconnected systems that make up our global economy.

Sensor technology has become an integral part of our daily lives, from the sensors in our smartphones that enable touchscreens to the sensors in our cars that help us park safely. These devices are essential for collecting data and providing feedback in a wide range of applications, from consumer electronics to industrial automation. In this article, we will explore the mainstream sensor production process, from the initial design phase to the final testing and packaging.The first step in sensor production is the design phase, where engineers and designers work together to create a sensor that meets the specific requirements of the application. This involves determining the type of sensor needed, such as temperature, pressure, or motion sensors, as well as the desired performance specifications, such as accuracy, sensitivity, and response time. Once the design is finalized, it is then translated into a detailed technical drawing that serves as the blueprint for the manufacturing process.The next step in sensor production is the fabrication of the sensor components. This typically involves the use of specialized materials and processes to create the sensor elements, such as the sensing element, signal conditioning circuitry, and packaging. For example, in the case of a temperature sensor, the sensing element may be made of a material that changes resistance with temperature, such as a thermistor or a platinum RTD (resistance temperature detector). The signal conditioning circuitry is then added to convert the resistance change into a measurable output signal, such as voltage or current.Once the sensor components are fabricated, they are assembled into a complete sensor device. This involves mounting the sensing element onto a substrate, connecting it to the signal conditioning circuitry, and encapsulating the entire assembly in a protective housing. The assembly process may involve a combination of automated machinery and manual labor, depending on the complexity of the sensor design and the volume of production.After the sensor device is assembled, it undergoes a series of tests to ensure that it meets the specified performance criteria. This typically involves testing the sensor's sensitivity, accuracy, and response time under various operating conditions, such as temperature, humidity, and vibration. Any sensors that fail to meet the required specifications are rejected and either repaired or discarded.Once the sensors have passed the testing phase, they are ready for packaging. This involves placing the sensors in a protective housing that shields them from environmental factors, such as moisture, dust, and mechanical shock. The packaging also includes the necessary electrical connections, such as wires or connectors, to interface the sensor with the external system.Finally, the packaged sensors are ready for distribution to customers. This may involve shipping the sensors to manufacturers who incorporate them into their products, such as smartphones, cars, or industrial equipment. Alternatively, the sensors may be sold directly to end-users for use in DIY projects or research applications.In conclusion, the mainstream sensor production process involves a series of steps, from the initial design phase to the final testing and packaging. This process requires a combination of engineering expertise, specialized materials, and manufacturing techniques to create sensors that meet the specific requirements of a wide range of applications. As sensor technology continues to advance, the production process will likely evolve to incorporate new materials, processes, and testing methods to meet the growing demand for sensors in our increasingly connected world.

In today's fast-paced world, technology plays a crucial role in almost every aspect of our lives. From smartphones to smart homes, technology has become an integral part of our daily routines. One of the key components of modern technology is module products. These products are designed to be easily integrated into various systems, making them versatile and efficient for a wide range of practical applications.Module products are essentially pre-built components that can be easily added to a larger system to enhance its functionality. These modules are designed to perform specific tasks or functions, such as processing data, controlling devices, or providing connectivity. By using module products, developers can save time and resources by not having to build these components from scratch.One of the key advantages of module products is their modularity. This means that they can be easily swapped in and out of a system without affecting the overall functionality. This flexibility allows developers to quickly adapt their systems to changing requirements or upgrade them with new features. For example, a developer working on a smart home system can easily add a new module for controlling lights or thermostats without having to redesign the entire system.Another important role of module products is their scalability. These products are designed to be easily scaled up or down to meet the needs of different applications. For example, a developer working on a robotics project can start with a basic module for controlling motors and sensors and then add more modules as needed to add new capabilities, such as vision processing or communication.Module products also play a crucial role in reducing development time and costs. By using pre-built modules, developers can focus on the core functionality of their systems without having to worry about building and testing every component from scratch. This can significantly speed up the development process and allow developers to bring their products to market faster.In addition to saving time and resources, module products also help improve the reliability and quality of systems. These products are typically designed and tested by experienced manufacturers, ensuring that they meet high standards of performance and reliability. By using module products, developers can leverage the expertise of these manufacturers to build robust and reliable systems.Module products are used in a wide range of practical applications across various industries. In the automotive industry, module products are used in vehicle control systems, navigation systems, and infotainment systems. In the healthcare industry, module products are used in medical devices, patient monitoring systems, and diagnostic equipment. In the industrial sector, module products are used in automation systems, robotics, and control systems.Overall, module products play a crucial role in modern technology by providing developers with versatile, scalable, and reliable components for building complex systems. By using these products, developers can save time and resources, improve the quality and reliability of their systems, and quickly adapt to changing requirements. As technology continues to advance, the role of module products will only become more important in driving innovation and progress in various industries.

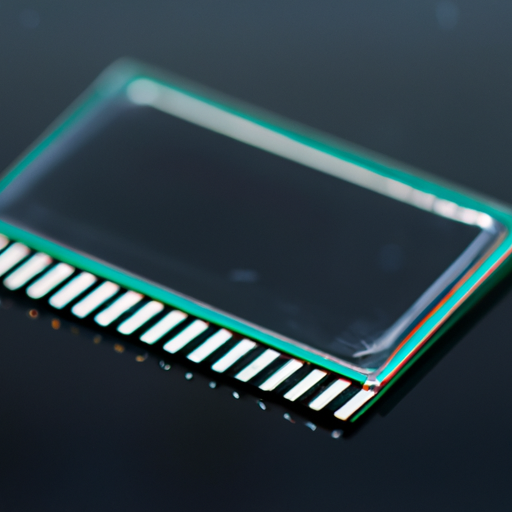

When it comes to selling storage cards, product training is essential for ensuring that sales representatives are knowledgeable and equipped to effectively promote and sell the product. Storage cards, also known as memory cards, are used in a variety of electronic devices such as cameras, smartphones, and tablets to store photos, videos, music, and other data. With the increasing demand for storage cards, it is important for sales representatives to have a thorough understanding of the product in order to effectively communicate its features and benefits to customers.Here are some key considerations for product training when it comes to selling storage cards:1. Understanding the different types of storage cards: There are several types of storage cards available on the market, including SD cards, microSD cards, CompactFlash cards, and more. Sales representatives should be familiar with the different types of storage cards and their respective features and specifications. This knowledge will enable them to recommend the most suitable storage card for a customer's specific needs.2. Knowing the storage capacity: Storage cards come in various storage capacities, ranging from a few gigabytes to several terabytes. Sales representatives should be able to explain the differences in storage capacity and help customers choose the right storage card based on their storage requirements. They should also be able to explain how the storage capacity of a card affects the number of photos, videos, or other data that can be stored on it.3. Understanding speed ratings: Storage cards come with speed ratings that indicate how quickly data can be read from or written to the card. Sales representatives should be familiar with speed ratings such as Class 4, Class 10, UHS-I, and UHS-II, and be able to explain how these ratings impact the performance of the storage card. This knowledge will help customers choose a storage card that meets their speed requirements, especially for tasks such as recording high-definition videos or capturing fast-action shots.4. Explaining compatibility: Storage cards are designed to be compatible with specific devices, so it is important for sales representatives to understand which storage cards are compatible with different devices. They should be able to explain the compatibility of storage cards with cameras, smartphones, tablets, and other electronic devices, and help customers choose a storage card that is compatible with their device.5. Highlighting durability and reliability: Storage cards are often used in demanding environments, such as outdoor adventures or extreme weather conditions. Sales representatives should be able to explain the durability and reliability of storage cards, including features such as waterproof, shockproof, and temperature-resistant designs. This knowledge will help customers choose a storage card that can withstand the rigors of their activities.6. Providing tips for care and maintenance: Proper care and maintenance of storage cards are essential for ensuring their longevity and performance. Sales representatives should be able to provide customers with tips for handling, storing, and cleaning storage cards, as well as advice on how to prevent data loss or corruption. This information will help customers protect their valuable data and get the most out of their storage card.7. Demonstrating how to use storage cards: In addition to explaining the features and benefits of storage cards, sales representatives should be able to demonstrate how to use storage cards with different devices. This may include showing customers how to insert and remove a storage card, format a storage card, transfer data to and from a storage card, and troubleshoot common issues. Hands-on demonstrations can help customers feel more confident in using storage cards and increase their satisfaction with the product.In conclusion, product training is essential for sales representatives to effectively promote and sell storage cards. By understanding the different types of storage cards, knowing the storage capacity and speed ratings, explaining compatibility, highlighting durability and reliability, providing tips for care and maintenance, and demonstrating how to use storage cards, sales representatives can enhance their product knowledge and better assist customers in choosing the right storage card for their needs. With the increasing demand for storage cards, investing in product training can help sales representatives increase sales, build customer trust, and drive business success.

Storage card products play a crucial role in today's digital world, where the need for storing and accessing large amounts of data is ever-increasing. These products, such as SD cards, microSD cards, and CompactFlash cards, provide a convenient and portable solution for storing photos, videos, music, documents, and other types of files. In practical applications, storage card products are used in a wide range of devices, including digital cameras, smartphones, tablets, laptops, gaming consoles, and more.One of the key advantages of storage card products is their portability. These small and lightweight cards can be easily carried around and inserted into various devices, allowing users to access their data wherever they go. This makes them ideal for professionals who need to transfer files between different devices, such as photographers who need to quickly offload photos from their camera to a computer or tablet.In addition to their portability, storage card products also offer high storage capacities, allowing users to store large amounts of data in a compact form factor. For example, microSD cards can now offer capacities of up to 1TB, making them suitable for storing high-resolution photos and videos, as well as large music and video libraries. This high storage capacity is particularly useful for users who need to store a large amount of data on their devices, such as content creators, videographers, and gamers.Another key advantage of storage card products is their durability and reliability. Unlike traditional hard drives, which have moving parts that can fail over time, storage card products are solid-state devices that are more resistant to physical damage. This makes them ideal for use in rugged environments, such as outdoor photography shoots or extreme sports activities, where traditional hard drives may be more prone to failure.Furthermore, storage card products offer fast read and write speeds, allowing users to quickly transfer files between devices. This is particularly important for professionals who need to work with large files, such as photographers who need to quickly transfer photos from their camera to a computer for editing. The fast read and write speeds of storage card products help to streamline workflows and improve productivity.In practical applications, storage card products are used in a wide range of industries and professions. For example, in the photography industry, storage card products are essential for storing high-resolution photos and videos captured by digital cameras. Photographers rely on storage card products to safely store their work and transfer it to computers for editing and sharing with clients.Similarly, in the video production industry, storage card products are used to store raw footage and edited videos, allowing filmmakers to work on their projects on the go. Storage card products are also used in the music industry, where musicians and producers use them to store audio recordings and samples for their music projects.In the gaming industry, storage card products are used in gaming consoles to store game data, updates, and downloadable content. Gamers can expand the storage capacity of their consoles by using storage card products, allowing them to store more games and media files.In the education sector, storage card products are used in schools and universities to store educational materials, such as e-books, videos, and presentations. Students and teachers can easily transfer files between devices using storage card products, making it easier to access and share educational resources.Overall, storage card products play a vital role in practical applications across various industries and professions. Their portability, high storage capacity, durability, reliability, and fast read and write speeds make them an essential tool for storing and accessing data in today's digital world. Whether you are a photographer, filmmaker, musician, gamer, student, or professional, storage card products offer a convenient and efficient solution for managing your data.

Choosing the right spot manager is a crucial decision for any business. The spot manager is responsible for overseeing the day-to-day operations of a business, ensuring that everything runs smoothly and efficiently. They are also responsible for managing the staff, handling customer complaints, and making sure that the business is profitable.When choosing a spot manager, there are several factors to consider. Here are some tips to help you make the right decision:1. Experience: One of the most important factors to consider when choosing a spot manager is their experience. Look for someone who has a proven track record of success in managing a business. They should have experience in the industry in which your business operates and should have a good understanding of the challenges and opportunities that come with running a business.2. Leadership skills: A good spot manager should have strong leadership skills. They should be able to motivate and inspire their team, delegate tasks effectively, and make tough decisions when necessary. Look for someone who has a track record of leading teams to success and who can handle difficult situations with grace and professionalism.3. Communication skills: Effective communication is key to successful spot management. Your spot manager should be able to communicate clearly and effectively with staff, customers, and other stakeholders. They should be able to listen to feedback, address concerns, and keep everyone informed about important developments within the business.4. Financial acumen: A good spot manager should have a solid understanding of financial management. They should be able to create and manage budgets, analyze financial reports, and make strategic decisions to ensure the financial health of the business. Look for someone who is comfortable working with numbers and who has a track record of making sound financial decisions.5. Problem-solving skills: Running a business is not always smooth sailing, and your spot manager should be able to handle challenges and solve problems effectively. Look for someone who is resourceful, creative, and able to think on their feet. They should be able to come up with solutions to problems quickly and efficiently, and be able to adapt to changing circumstances.6. Cultural fit: Finally, it's important to consider the cultural fit between the spot manager and your business. Look for someone who shares your values and vision for the business, and who will be able to work well with your existing team. A good spot manager should be able to build strong relationships with staff and customers, and create a positive and inclusive work environment.In conclusion, choosing the right spot manager is a critical decision for any business. By considering factors such as experience, leadership skills, communication skills, financial acumen, problem-solving skills, and cultural fit, you can make an informed decision that will benefit your business in the long run. Take the time to carefully evaluate potential candidates and choose someone who will help your business thrive.

When it comes to choosing the right electric wire component for your project, there are a few key factors to consider. From the type of wire insulation to the gauge of the wire, each component plays a crucial role in ensuring the safety and efficiency of your electrical system. In this article, we will discuss the different classes of electric wire components and provide recommendations for each class.Class 1: Insulation MaterialThe insulation material of an electric wire component is one of the most important factors to consider. The insulation material not only protects the wire from external elements but also prevents electrical shocks and short circuits. There are several types of insulation materials available, including PVC, rubber, and Teflon.For general-purpose applications, PVC insulation is a popular choice due to its affordability and flexibility. PVC insulation is suitable for indoor use and can withstand moderate temperatures. However, for more demanding applications that require resistance to high temperatures and chemicals, Teflon insulation is recommended. Teflon insulation is highly durable and can withstand extreme conditions, making it ideal for industrial and automotive applications.Rubber insulation is another option that offers excellent flexibility and resistance to abrasion. Rubber insulation is commonly used in portable tools and appliances where flexibility is essential. When choosing the insulation material for your electric wire component, consider the environmental conditions and temperature requirements of your application to ensure optimal performance.Class 2: Wire GaugeThe wire gauge of an electric wire component refers to the thickness of the wire. The wire gauge is an important factor to consider as it determines the current-carrying capacity of the wire. The higher the gauge number, the thinner the wire and the lower the current-carrying capacity. Conversely, the lower the gauge number, the thicker the wire and the higher the current-carrying capacity.When selecting the wire gauge for your electric wire component, it is essential to consider the maximum current that will flow through the wire. The American Wire Gauge (AWG) system is commonly used to specify wire gauge sizes, with lower AWG numbers indicating thicker wires. For example, a 10 AWG wire has a higher current-carrying capacity than a 16 AWG wire.For applications that require high current-carrying capacity, such as industrial machinery and power distribution systems, it is recommended to use a lower gauge wire to prevent overheating and voltage drop. On the other hand, for low-power applications such as lighting fixtures and small appliances, a higher gauge wire may be sufficient. Consider the current requirements of your application when selecting the wire gauge for your electric wire component.Class 3: Conductor MaterialThe conductor material of an electric wire component plays a crucial role in determining the conductivity and durability of the wire. Copper and aluminum are the two most common conductor materials used in electric wires. Copper is preferred for its high conductivity and resistance to corrosion, making it ideal for most electrical applications.Aluminum is a cost-effective alternative to copper and is commonly used in power distribution systems and overhead transmission lines. While aluminum has a lower conductivity than copper, it is lightweight and offers good corrosion resistance. When selecting the conductor material for your electric wire component, consider the conductivity requirements and budget constraints of your project.In conclusion, choosing the right electric wire component is essential for ensuring the safety and efficiency of your electrical system. Consider the insulation material, wire gauge, and conductor material of the wire when selecting the components for your project. By following these recommendations, you can ensure that your electric wire component meets the requirements of your application and performs reliably for years to come.

The cable industry is a crucial part of the global economy, providing essential services for communication, entertainment, and data transmission. As technology continues to advance, the importance of patents related to cable innovations has become increasingly significant. In this article, we will explore some of the key industries that contain important patents related to cable technology.1. Telecommunications IndustryThe telecommunications industry is one of the primary sectors that rely heavily on cable technology for the transmission of voice, data, and video signals. Patents related to fiber optic cables, coaxial cables, and other types of communication cables are essential for the development of high-speed internet, cable television, and telephone services.In recent years, there has been a surge in patents related to fiber optic cables, which are capable of transmitting data at incredibly high speeds over long distances. These patents cover various aspects of fiber optic technology, including cable design, manufacturing processes, and signal processing techniques.One of the key players in the telecommunications industry with a significant number of patents related to cable technology is Corning Incorporated. The company has a long history of innovation in the field of fiber optics and holds numerous patents for fiber optic cables, connectors, and related components.2. Electronics IndustryThe electronics industry is another important sector that relies on cable technology for the transmission of electrical signals within electronic devices. Patents related to cables used in consumer electronics, computers, and other electronic devices play a crucial role in the development of new products and technologies.Companies like Apple, Samsung, and Sony are known for their extensive patent portfolios related to cable technology. These patents cover a wide range of cable types, including USB cables, HDMI cables, and power cables, as well as innovative cable designs and connectors.In recent years, there has been a growing focus on wireless technologies in the electronics industry, leading to the development of new types of cables and connectors for wireless charging and data transfer. Patents related to wireless charging cables, magnetic connectors, and other wireless technologies are becoming increasingly important in this rapidly evolving industry.3. Automotive IndustryThe automotive industry is another sector that relies on cable technology for a wide range of applications, including vehicle wiring, sensors, and communication systems. Patents related to automotive cables are essential for the development of advanced safety features, infotainment systems, and electric vehicle technology.Companies like Bosch, Delphi, and TE Connectivity are leading players in the automotive cable industry and hold numerous patents related to cable technology for vehicles. These patents cover a wide range of automotive cables, connectors, and wiring harnesses, as well as innovative cable designs for electric and autonomous vehicles.In recent years, there has been a growing focus on electric vehicle technology in the automotive industry, leading to the development of new types of cables and connectors for electric vehicle charging and power distribution. Patents related to electric vehicle cables, charging stations, and battery management systems are becoming increasingly important as the demand for electric vehicles continues to grow.4. Energy IndustryThe energy industry is another sector that relies on cable technology for the transmission of electrical power from generation sources to end-users. Patents related to power cables, transmission lines, and grid infrastructure are essential for the development of reliable and efficient energy systems.Companies like Prysmian Group, Nexans, and General Cable are leading players in the energy cable industry and hold numerous patents related to cable technology for power transmission and distribution. These patents cover a wide range of power cables, connectors, and accessories, as well as innovative cable designs for renewable energy systems and smart grid technology.In recent years, there has been a growing focus on renewable energy sources in the energy industry, leading to the development of new types of cables and connectors for solar, wind, and other renewable energy systems. Patents related to renewable energy cables, grid integration technologies, and energy storage systems are becoming increasingly important as the world transitions to a more sustainable energy future.ConclusionIn conclusion, patents related to cable technology play a crucial role in a wide range of industries, including telecommunications, electronics, automotive, and energy. Companies that hold important patents related to cable technology have a competitive advantage in their respective industries and are well-positioned to drive innovation and growth in the global economy.As technology continues to advance, the importance of patents related to cable innovations will only continue to grow. Companies that invest in research and development of new cable technologies and protect their innovations through patents will be able to stay ahead of the competition and capitalize on the opportunities presented by the evolving cable industry.

Choosing the right spot cable component is crucial for ensuring optimal performance and reliability in your cable system. With so many options available on the market, it can be overwhelming to decide which one is best suited for your specific needs. In this article, we will discuss the key factors to consider when selecting a spot cable component and provide some tips to help you make an informed decision.1. Understand your requirements: Before you start looking for a spot cable component, it is important to understand your specific requirements. Consider factors such as the type of cable you are using, the environment in which it will be installed, and the performance specifications you need to meet. This will help you narrow down your options and focus on components that are best suited for your application.2. Quality and reliability: When it comes to spot cable components, quality and reliability are paramount. Look for components that are made from high-quality materials and have been tested to meet industry standards. It is also important to choose components from reputable manufacturers with a track record of producing reliable products. Investing in high-quality components may cost more upfront, but it will save you time and money in the long run by reducing the risk of failures and downtime.3. Compatibility: Make sure that the spot cable component you choose is compatible with your existing cable system. Check the specifications of the component to ensure that it is suitable for the type of cable you are using and that it meets the required performance standards. Using incompatible components can lead to signal loss, interference, and other issues that can affect the overall performance of your cable system.4. Environmental considerations: Consider the environment in which the spot cable component will be installed. If the component will be exposed to harsh conditions such as extreme temperatures, moisture, or vibrations, make sure to choose a component that is designed to withstand these challenges. Look for components that are rated for outdoor use or have protective coatings to ensure long-term reliability in challenging environments.5. Cost: While cost is an important factor to consider, it should not be the only consideration when choosing a spot cable component. It is important to strike a balance between cost and quality to ensure that you are getting the best value for your money. Consider the total cost of ownership, including installation, maintenance, and potential downtime, when evaluating different options.6. Consult with experts: If you are unsure about which spot cable component to choose, consider consulting with experts in the field. They can provide valuable insights and recommendations based on their experience and knowledge of the industry. They can also help you navigate the technical specifications and select the best component for your specific needs.In conclusion, choosing the right spot cable component is essential for ensuring the performance and reliability of your cable system. By considering factors such as quality, compatibility, environmental considerations, cost, and consulting with experts, you can make an informed decision that meets your specific requirements. Remember that investing in high-quality components will pay off in the long run by reducing the risk of failures and ensuring the long-term performance of your cable system.

Cable components are an essential part of many different products and systems, providing the necessary connections for power, data, and communication. These components come in a wide variety of types and configurations, each designed for specific applications and requirements. In this article, we will explore the different types of cable components and their uses in various industries.1. Power cables: Power cables are used to transmit electrical power from a source to a device or system. These cables are typically made of copper or aluminum conductors surrounded by insulation and a protective sheath. Power cables come in various sizes and configurations, depending on the amount of power they need to carry and the environment in which they will be used. Power cables are commonly used in residential, commercial, and industrial applications to provide electricity to appliances, machinery, and other devices.2. Data cables: Data cables are used to transmit digital data between devices, such as computers, printers, and networking equipment. These cables are typically made of twisted pairs of copper wires surrounded by insulation and a protective sheath. Data cables come in various types, including Ethernet cables, USB cables, and HDMI cables, each designed for specific data transmission requirements. Data cables are essential for connecting devices to each other and to the internet, enabling communication and data transfer.3. Coaxial cables: Coaxial cables are used to transmit high-frequency signals, such as those used in cable television, satellite TV, and internet connections. These cables consist of a central conductor surrounded by insulation, a metallic shield, and an outer protective sheath. Coaxial cables are designed to minimize signal loss and interference, making them ideal for high-speed data transmission. Coaxial cables are commonly used in telecommunications, broadcasting, and networking applications.4. Fiber optic cables: Fiber optic cables are used to transmit data using light signals instead of electrical signals. These cables consist of a core made of glass or plastic fibers surrounded by a protective sheath. Fiber optic cables are capable of transmitting data at high speeds over long distances, making them ideal for telecommunications, internet connections, and data centers. Fiber optic cables are known for their high bandwidth, low latency, and immunity to electromagnetic interference, making them a popular choice for high-speed data transmission.5. Ribbon cables: Ribbon cables are flat, flexible cables that contain multiple conductors arranged in a parallel configuration. These cables are commonly used in electronic devices and systems where space is limited, such as computers, printers, and automotive applications. Ribbon cables are designed to provide a compact and organized way to connect multiple components within a system, reducing clutter and improving airflow. Ribbon cables are available in various configurations, including IDC (insulation displacement connector) and D-sub connectors, making them versatile and easy to use.6. Cable assemblies: Cable assemblies are pre-assembled cables that include connectors, terminals, and other components for easy installation and connection. These assemblies are designed to provide a plug-and-play solution for connecting devices and systems, saving time and labor. Cable assemblies come in various types, including custom cables, standard cables, and specialty cables, each tailored to specific applications and requirements. Cable assemblies are commonly used in automotive, aerospace, and industrial applications where reliable and durable connections are essential.In conclusion, cable components play a crucial role in powering, connecting, and transmitting data in a wide range of products and systems. From power cables to fiber optic cables, each type of cable component serves a specific purpose and application, enabling the seamless operation of devices and equipment. By understanding the different types of cable components and their uses, manufacturers and engineers can choose the right cables for their specific needs, ensuring reliable and efficient performance.

Interconnection devices are essential components in various electronic systems, enabling the connection and communication between different devices and components. These devices play a crucial role in ensuring the smooth operation of electronic systems, such as computers, smartphones, and networking equipment. There are several common production processes involved in the manufacturing of interconnection devices, each of which contributes to the overall quality and performance of the final product.1. Design and PrototypingThe first step in the production of interconnection devices is the design and prototyping phase. During this stage, engineers and designers work together to create a detailed blueprint of the device, taking into account factors such as size, shape, material, and functionality. Prototyping allows for testing and validation of the design before mass production begins, ensuring that any potential issues are identified and addressed early on.2. Material SelectionThe choice of materials used in the production of interconnection devices is critical to their performance and durability. Common materials used in the manufacturing of interconnection devices include metals such as copper, aluminum, and gold, as well as plastics and ceramics. The selection of materials is based on factors such as conductivity, corrosion resistance, and mechanical strength, ensuring that the final product meets the required specifications.3. Manufacturing ProcessesThere are several common manufacturing processes used in the production of interconnection devices, each of which plays a crucial role in shaping the final product. Some of the most common manufacturing processes include:- Stamping: Stamping is a process in which metal sheets are cut and formed into the desired shape using a die and press. This process is commonly used in the production of connectors and terminals for interconnection devices.- Injection Molding: Injection molding is a process in which molten plastic is injected into a mold cavity, where it cools and solidifies to form the final product. This process is commonly used in the production of plastic connectors and housings for interconnection devices.- Plating: Plating is a process in which a thin layer of metal is deposited onto the surface of a substrate to improve conductivity, corrosion resistance, and appearance. Common plating materials used in the production of interconnection devices include gold, silver, and tin.- Assembly: Assembly is the process of combining individual components to create the final interconnection device. This may involve soldering, welding, or mechanical fastening, depending on the design and requirements of the device.4. Quality ControlQuality control is an essential aspect of the production process for interconnection devices, ensuring that each device meets the required specifications and standards. Quality control measures may include visual inspection, dimensional measurements, electrical testing, and environmental testing to ensure that the devices are free from defects and meet the required performance criteria.5. Packaging and ShippingOnce the interconnection devices have been manufactured and passed quality control, they are packaged and prepared for shipping to customers. Packaging is important to protect the devices during transit and storage, ensuring that they arrive in good condition. Packaging may include anti-static bags, foam inserts, and protective boxes to prevent damage during shipping.In conclusion, the production of interconnection devices involves a series of complex processes, from design and prototyping to manufacturing, quality control, and packaging. Each of these processes plays a crucial role in shaping the final product and ensuring that it meets the required specifications and standards. By following best practices in manufacturing and quality control, manufacturers can produce high-quality interconnection devices that meet the needs of their customers and contribute to the overall performance of electronic systems.

Connector is a powerful tool that allows users to integrate different systems and applications, enabling seamless communication and data exchange between them. It is a versatile platform that offers a wide range of components and modules to meet the diverse needs of businesses and organizations. In this article, we will explore the various components and modules that Connector contains, and how they can be used to streamline workflows and improve efficiency.1. Data Integration Module:

One of the key components of Connector is its data integration module, which allows users to connect and synchronize data between different systems. This module supports a variety of data formats and protocols, making it easy to transfer data between applications, databases, and cloud services. With the data integration module, users can automate data transfers, schedule synchronization tasks, and ensure that data is always up-to-date and accurate.2. Workflow Automation Module:

Connector also includes a workflow automation module, which enables users to create custom workflows and automate repetitive tasks. This module allows users to define triggers, conditions, and actions to automate complex business processes. With the workflow automation module, users can streamline workflows, reduce manual errors, and improve productivity.3. API Integration Module:

Connector offers an API integration module that allows users to connect to external APIs and web services. This module supports a wide range of APIs, including REST, SOAP, and GraphQL, making it easy to integrate with popular services such as Salesforce, Google, and Microsoft. With the API integration module, users can access and manipulate data from external sources, enabling them to build powerful integrations and extend the functionality of their applications.4. Real-Time Monitoring Module:

Connector includes a real-time monitoring module that allows users to track the performance and status of their integrations. This module provides real-time insights into data transfers, workflow executions, and API calls, enabling users to monitor and troubleshoot issues as they arise. With the real-time monitoring module, users can ensure that their integrations are running smoothly and efficiently.5. Security and Compliance Module:

Connector prioritizes security and compliance, and includes a dedicated module to help users protect their data and ensure regulatory compliance. This module offers features such as data encryption, access controls, and audit trails, enabling users to secure sensitive information and meet industry-specific regulations. With the security and compliance module, users can rest assured that their data is safe and secure.6. Customization and Extensibility Module:

Connector is highly customizable and extensible, allowing users to tailor the platform to their specific needs. The customization and extensibility module enables users to create custom connectors, plugins, and scripts, enabling them to integrate with proprietary systems and extend the functionality of Connector. With this module, users can build custom solutions that meet their unique requirements and drive innovation within their organization.In conclusion, Connector is a comprehensive integration platform that offers a wide range of components and modules to help users connect, automate, and optimize their workflows. From data integration and workflow automation to API integration and real-time monitoring, Connector provides the tools and capabilities needed to streamline processes, improve efficiency, and drive business success. Whether you are looking to integrate systems, automate tasks, or ensure data security and compliance, Connector has the features and functionality to meet your needs.

The purchase price of the latest discrete semiconductor products can vary depending on the specific product and manufacturer. Discrete semiconductors are individual electronic components that perform a specific function within an electronic circuit, such as diodes, transistors, and rectifiers. These components are essential for the operation of electronic devices and are used in a wide range of applications, from consumer electronics to industrial equipment.One of the key factors that determine the purchase price of discrete semiconductor products is the type of semiconductor material used in their construction. Silicon is the most commonly used material for discrete semiconductors, but other materials such as gallium arsenide and silicon carbide are also used in certain applications. The cost of these materials can vary depending on factors such as availability, purity, and manufacturing processes.Another factor that influences the purchase price of discrete semiconductor products is the complexity of the component. More complex components, such as power transistors and integrated circuits, typically have higher prices due to the additional materials and manufacturing processes required to produce them. On the other hand, simpler components like diodes and resistors are generally more affordable.In addition to the type of semiconductor material and complexity of the component, other factors that can affect the purchase price of discrete semiconductor products include the manufacturer, quantity purchased, and market demand. Some manufacturers may charge higher prices for their products due to factors such as brand reputation, product quality, and customer service. The quantity purchased can also impact the price, as bulk orders may be eligible for discounts or special pricing arrangements. Market demand can also influence the price of discrete semiconductor products, with high-demand products typically commanding higher prices.Overall, the purchase price of the latest discrete semiconductor products can range from a few cents for simple components like diodes and resistors to hundreds of dollars for more complex components like power transistors and integrated circuits. It is important for buyers to carefully consider their specific requirements and budget constraints when selecting discrete semiconductor products for their electronic projects.In conclusion, the purchase price of the latest discrete semiconductor products can vary depending on a variety of factors, including the type of semiconductor material, complexity of the component, manufacturer, quantity purchased, and market demand. Buyers should carefully consider these factors when selecting discrete semiconductor products for their electronic projects to ensure they get the best value for their investment.

In today's rapidly evolving technology landscape, the demand for separate semiconductor products and device components is higher than ever before. These components are essential for the functioning of various electronic devices, from smartphones and laptops to cars and industrial machinery. As a result, manufacturers and suppliers of these components are constantly looking for new and innovative ways to meet the needs of their customers.One of the key aspects of purchasing separate semiconductor products and device components is the purchasing model. This refers to the way in which these components are bought and sold, and can have a significant impact on the overall cost and efficiency of the supply chain. In this article, we will explore some of the most common purchasing models for separate semiconductor products and device components, and discuss their advantages and disadvantages.1. Direct purchasingDirect purchasing is perhaps the most traditional model for buying separate semiconductor products and device components. In this model, the buyer deals directly with the manufacturer or supplier of the components, without the involvement of any intermediaries. This can be a cost-effective option, as it eliminates the need for middlemen and allows for direct negotiation of prices and terms.However, direct purchasing can also have its drawbacks. For one, it requires a significant amount of time and effort to establish relationships with multiple suppliers and manage the procurement process. Additionally, buyers may not have access to the same level of expertise and support that they would get from a distributor or reseller.2. Distributor purchasingDistributor purchasing is another common model for buying separate semiconductor products and device components. In this model, the buyer purchases the components from a distributor, who acts as an intermediary between the manufacturer and the end user. Distributors typically carry a wide range of products from multiple manufacturers, making it easier for buyers to find the components they need.One of the main advantages of distributor purchasing is the convenience and efficiency it offers. Buyers can access a wide range of products from multiple suppliers through a single point of contact, saving time and effort. Distributors also provide value-added services such as technical support, inventory management, and logistics, which can help streamline the procurement process.However, distributor purchasing can also come with its own set of challenges. Distributors may add a markup to the cost of the components, increasing the overall price for the buyer. Additionally, buyers may have less control over the quality and availability of the components, as they are reliant on the distributor's inventory and supply chain.3. Value-added reseller (VAR) purchasingValue-added resellers (VARs) are another important player in the separate semiconductor products and device components market. VARs purchase components from manufacturers or distributors, and then add value to them through customization, integration, or other services before selling them to end users. This model allows buyers to access specialized expertise and customized solutions that may not be available through other channels.One of the key advantages of VAR purchasing is the ability to access customized solutions that meet specific requirements. VARs can provide tailored solutions that address the unique needs of the buyer, such as custom configurations, integration with existing systems, or specialized testing and validation. This can help buyers achieve greater efficiency and performance in their electronic devices.However, VAR purchasing can also be more expensive than other models, as the added value and customization services come at a cost. Buyers may also face longer lead times and more complex procurement processes when working with VARs, as compared to buying directly from manufacturers or distributors.4. Online purchasingWith the rise of e-commerce and online marketplaces, online purchasing has become an increasingly popular model for buying separate semiconductor products and device components. Online platforms allow buyers to browse and purchase components from a wide range of suppliers, often at competitive prices and with fast delivery times. This model offers convenience and accessibility, making it easier for buyers to find the components they need quickly and efficiently.One of the main advantages of online purchasing is the ability to access a wide range of products from multiple suppliers in one place. Online platforms often offer advanced search and filtering tools that make it easy for buyers to find the components they need, as well as customer reviews and ratings that can help inform their purchasing decisions. Online purchasing also allows for easy comparison of prices and features, helping buyers make informed choices.However, online purchasing can also have its drawbacks. Buyers may face challenges in verifying the quality and authenticity of the components they are purchasing, as they are not able to physically inspect the products before buying. Additionally, online platforms may not offer the same level of technical support and expertise that buyers would get from working directly with manufacturers or distributors.In conclusion, there are several purchasing models available for buying separate semiconductor products and device components, each with its own advantages and disadvantages. Whether buyers choose to purchase directly from manufacturers, through distributors, from value-added resellers, or online, it is important to consider factors such as cost, convenience, expertise, and customization when making their purchasing decisions. By understanding the different purchasing models and their implications, buyers can make informed choices that meet their specific needs and requirements in today's fast-paced technology market.